मरà¥à¤¨ हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸

Price 10000 आईएनआर/ टुकड़ा

मरà¥à¤¨ हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸ Specification

- तापमान

- व्यास

- 120-250 mm

- पाइप की संख्या

- 20-60 tubes

- अधिकतम दबाव

- 2.5 MPa

- मोटाई

- 3-5 mm

- मैक्स। क्षमता

- up to 30000 Kcal/hr

- शर्त

- स्ट्रक्चर

- लिक्विड फ्लो रेट

- 1.2-5.8 m³/h

- काम का दबाव

- 1.0-2.5 MPa

- वोल्टेज

- 220-380 V

- पावर

- 5-25 kW

- वज़न

- 30-50 kg

- आयाम

- 600 x 225 x 250 mm

मरà¥à¤¨ हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸ Trade Information

- Minimum Order Quantity

- 5 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About मरà¥à¤¨ हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸

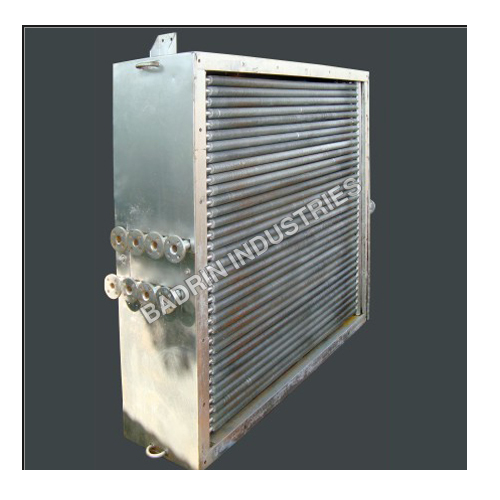

Under the meticulous control of our diligent technocrats, we are offering Marine Heat Exchangers for our esteemed clients. These exchangers are manufactured using premium quality components. Provided exchangers find their wide application in marine ships for transferring heat and cooling purposes. These exchangers are available by us in several specifications at rock bottom rates. अधिकover, our valued patrons can get these Marine Heat Exchangers from us in bulk.

Marine Heat Exchangers come in superior grade stainless steel 316L/titanium material finish which makes these deliver optimum working performance. Further, its compact size finish also makes these provide for superior usage. Some of its features include ensures high viscosity oil with good flow velocity inside unit; high heating efficiency for oil cooling; provides for easy installation support; maximum working pressure on oil side of 25 bar; maximum working pressure on water side of 3 bar, 10 bar, 15 bar.

Key Points of Marine Heat Exchangers:

- Smooth operation

- Trouble free functioning

- Require low maintenance

- High durability

Superior Corrosion Resistance

Constructed from copper, brass, or stainless steel, these marine heat exchangers exhibit exceptional resistance to corrosion, making them ideal for harsh maritime and industrial environments. This robust material selection extends operational life and minimizes downtime due to maintenance.

Efficient Heat Transfer

Each unit features a shell and tube design, maximizing heat transfer efficiency across a surface area of 0.6-2.4 m. With up to 60 tubes per exchanger, they effectively regulate temperature in marine engines, HVAC systems, and power generation applications.

Flexible Installation Options

Designed for versatile use, these heat exchangers support both horizontal and vertical mounting, ensuring convenient integration in confined marine engine rooms or industrial setups. Threaded and flanged end connections make installation and future servicing straightforward.

FAQs of Marine Heat Exchangers:

Q: How do marine heat exchangers enhance engine performance?

A: Marine heat exchangers regulate engine temperature by transferring excess heat away from machinery, helping maintain optimum operational conditions and prolonging engine life. Their high heat transfer efficiency reduces the risk of overheating during continuous operations.Q: What materials are used in these marine heat exchangers, and why?

A: The exchangers are made from copper, brass, or stainless steel, selected for their exceptional resistance to corrosion and durability. These materials withstand harsh marine conditions and exposure to saltwater, offering long-term reliability.Q: When should these heat exchangers be serviced or cleaned?

A: Thanks to their easy-to-clean design, routine inspection and cleaning are recommended during scheduled vessel or plant maintenance. Their low-maintenance structure helps prevent scale buildup and ensures consistent performance.Q: Where can these heat exchangers be installed?

A: Suitable for marine engines, HVAC systems, and power generation units, these exchangers can be installed horizontally or vertically. Their compact design and threaded/flanged connections allow flexible positioning in various onboard or industrial environments.Q: What is the process of installing the heat exchanger in a marine engine room?

A: Installation involves securing the unit in either horizontal or vertical orientation, connecting threaded or flanged ends to existing piping, and ensuring proper alignment for optimal fluid flow. The process is straightforward due to the modular structure and standard connection sizes.Q: What are the benefits of using this heat exchanger in a power generation application?

A: In power generation, these heat exchangers provide high thermal efficiency and robust corrosion resistance, resulting in improved operational stability, reduced maintenance costs, and enhanced equipment longevity.Q: How does the heat exchanger support varying flow rates and operating pressures?

A: The design accommodates liquid flow rates from 1.2 to 5.8 m/h and working pressures up to 2.5 MPa, making it suitable for handling diverse cooling requirements across marine, industrial, and HVAC applications.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Heat Exchangers Category

स्टेनलेस स्टील हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

व्यास : 150350 mm

शर्त : New

पावर : 520 kW (depending on application)

मैक्स। क्षमता : up to 12000 L/hr

आयाम : 1200 mm x 400 mm x 900 mm (varies by model)

हाई प्रेशर हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

व्यास : 600 mm

शर्त : New

पावर : 20 kW

मैक्स। क्षमता : 30,000 Kcal/hr

आयाम : 2200 mm x 600 mm x 1200 mm

पैडी ड्रायर हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

व्यास : 300 mm

शर्त : New

पावर : 510 kW

मैक्स। क्षमता : 1500 Kg/h

आयाम : Customization Available

कॉपर हीट एक्सचेंजर

मूल्य की इकाई : टुकड़ा/टुकड़े

व्यास : 32 mm (Outer Pipe), 16 mm (Inner Pipe)

शर्त : New

पावर : No Power Required

मैक्स। क्षमता : Up to 200 LPH

आयाम : 1200mm x 300mm x 350mm

|

BADRIN INDUSTRIES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें