राà¤à¤¸ मिल हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸

Price 10000 आईएनआर/ टुकड़ा

MOQ : 5 टुकड़ाs

राà¤à¤¸ मिल हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸ Specification

- मैक्स। क्षमता

- 7 Tons/hr

- एयर वॉल्यूम

- 4500 m³/h

- पाइप की संख्या

- 68

- तापमान

- अधिकतम दबाव

- 1.6 MPa

- मोटाई

- 8 mm

- व्यास

- 300 mm

- शर्त

- स्ट्रक्चर

- लिक्विड फ्लो रेट

- 6500 L/h

- काम का दबाव

- 1.0 MPa

- वोल्टेज

- 380 V

- पावर

- 15 kW

- वज़न

- 1200 kg

- आयाम

- 2100 x 700 x 1500 mm

राà¤à¤¸ मिल हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸ Trade Information

- Minimum Order Quantity

- 5 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About राà¤à¤¸ मिल हà¥à¤ à¤à¤à¥à¤¸à¤à¥à¤à¤à¤°à¥à¤¸

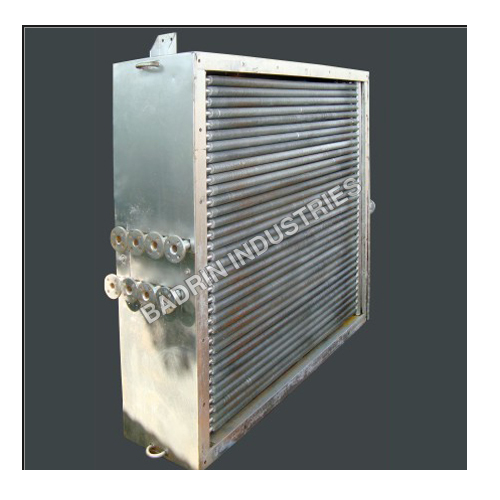

Having a well equipped production unit and technically skilled workforce, we are instrumental in offering a pristine quality range of Rice Mill Heat Exchangers. These exchangers are highly demanded in rice mills for heating rice grains to a certain temperature. These heat exchangers are manufactured by utilizing top grade components and modish techniques. Also, the Rice Mill Heat Exchangers are tested on certain quality aspects by our experts.

Features of Rice Mill Heat Exchangers:

- High functionality

- Strong construction

- Reliable operation

- Defect free design

Efficient Heat Exchange for Rice Mills

Designed specifically for rice mills and grain drying applications, our heat exchanger ensures uniform and rapid drying at optimal temperatures. The 24 m exchange area and 68-tube structure promote excellent thermal transfer while minimizing energy waste. Its floor-mounted, horizontal design allows integration into varied processing lines with ease, improving overall productivity and grain quality.

Exceptional Durability and Corrosion Resistance

Manufactured with high-grade stainless steel and an 8 mm thickness, the heat exchanger demonstrates outstanding resistance to corrosion, ensuring operational integrity even under humid and challenging mill conditions. With a proven service life of over 10 years and minimal maintenance needs, it reliably supports continuous rice processing operations year-round.

FAQs of Rice Mill Heat Exchangers:

Q: How does the stainless steel heat exchanger improve rice drying efficiency in mills?

A: The heat exchanger rapidly and uniformly transfers heat to the grains through its 68 stainless steel tubes and large 24 m surface area. This design reduces moisture content efficiently, speeds up drying, and enhances the final rice quality while saving energy.Q: What maintenance is required for a horizontal, floor-mounted heat exchanger in rice mills?

A: Thanks to its robust stainless steel construction and excellent corrosion resistance, maintenance is minimal. Routine checks for cleanliness and pressure levels are recommended, but the unit is designed for low-maintenance operation during its 10+ year service life.Q: When should I expect to replace the heat exchanger, given its service life?

A: Under normal operating conditions in rice mills, the heat exchanger is expected to last more than 10 years. Timely inspections and adherence to recommended usage guidelines will ensure its longevity and performance.Q: Where is this heat exchanger typically installed in rice mill facilities?

A: The heat exchanger is designed for floor mounting and horizontal orientation, fitting seamlessly into rice mill or grain drying lines. Its compact 2100 x 700 x 1500 mm dimensions allow convenient installation beside or integrated with existing dryers.Q: What is the process of operating the heat exchanger in a rice mill?

A: Connect the unit to a power supply (15 kW, 380 V), set operating parameters up to 150C and 1.0 MPa, and allow grain-laden air to pass through the unit. Liquid flows at 6500 L/h, efficiently transferring heat to ensure optimal grain drying.Q: What are the usage benefits of this stainless steel heat exchanger for grain drying?

A: Operating at up to 7 tons per hour and with an air volume of 4500 m/h, this heat exchanger enhances drying rates, lowers energy consumption, and produces uniformly dried grains, leading to reduced post-harvest losses and higher product quality.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Heat Exchangers Category

हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

मैक्स। क्षमता : Up to 50,000 kcal/hr

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 5

स्ट्रक्चर : ,

पावर : Up to 250 kW (depending on design)

ऑयल हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

मैक्स। क्षमता : 1000 L/H

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 5

स्ट्रक्चर : ,

पावर : 5 kW

मरीन हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

मैक्स। क्षमता : up to 30000 Kcal/hr

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 5

स्ट्रक्चर : ,

पावर : 525 kW

पैडी ड्रायर हीट एक्सचेंजर्स

मूल्य की इकाई : टुकड़ा/टुकड़े

मैक्स। क्षमता : 1500 Kg/h

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 5

स्ट्रक्चर : tube Heat Exchanger

पावर : 510 kW

|

BADRIN INDUSTRIES

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें