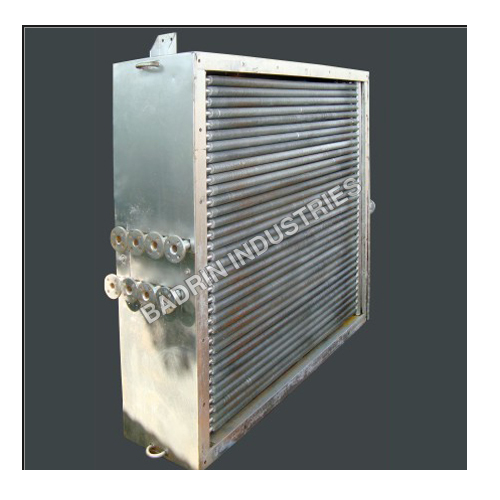

Paddy Dryer Heat Exchangers

Price 10000 INR/ Piece

Paddy Dryer Heat Exchangers Specification

- Temperature

- Up to 150C

- Air Volume

- 10000 m/h

- Thickness

- 5-10 mm

- Max Pressure

- 10 Bar

- Max. Capacity

- 1500 Kg/h

- Diameter

- 300 mm

- Condition

- New

- Structure

- tube Heat Exchanger

- Liquid Flow Rate

- 350 L/h

- Working Presssure

- 8 Bar

- Voltage

- 380 V

- Power

- 5-10 kW

- Weight

- 1000 Kg

- Dimensions

- Customization Available

- Design Standard

- IS 2825

- Application

- Paddy Drying System

- Corrosion Resistance

- Excellent

- Service Life

- 10 years

- Painting

- Epoxy Coated

- Heat Transfer Area

- 136 m²

- Efficiency

- 85%

- Installation Type

- Horizontal

- Material

- Stainless Steel

- Tube Material

- High-grade Copper

Paddy Dryer Heat Exchangers Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 3-4 Days

- Main Domestic Market

- All India

About Paddy Dryer Heat Exchangers

Among the trustworthy manufacturer, exporter and supplier, we are incorporated in manufacturing, exporting and supplying Paddy Dryer Heat Exchangers. For manufacturing these exchangers with high accuracy, our dexterous professionals make use of supreme quality components and innovative techniques. These exchangers are used in agricultural industry for drying paddy in less time. For the convenience of clients, we are offering these Paddy Dryer Heat Exchangers in numerous specification.

Paddy Dryer Heat Exchangers offeredcome designed and developed using attest technology support and are developed in superior grade stainless steel finish so as to offer lasting performance. These find application in precisely handling of air heating and cooling applications. Some of its features include stainless steel based finned tube in seamless construction finish; use of argon-arc welding on radiator; provides for superior anti corrosive performance; long service life; high thermal efficiency for effective heat transfer; compact design finish and others.

Features of Paddy Dryer Heat Exchangers:

- Rust proof finishing

- Low maintenance

- Resistant to breakage

- Easy to install

Optimized Heat Transfer for Paddy Dryers

Experience optimal heat transfer efficiency with our stainless steel paddy dryer heat exchangers. Engineered with high-grade copper tubes, these units maintain consistent performance at 85% efficiency, ensuring uniform drying and high energy savings in every cycle. Suitable for continuous operations, our exchangers withstand harsh working conditions and offer superior corrosion resistance for increased longevity.

Custom-Built Solutions for Your Facility

Every drying facility has unique requirements, which is why our paddy dryer heat exchangers come with customizable dimensions and a modular design. Whether you need adjustments in diameter, length, or heat transfer area, we cater to your specifications without compromising on performance or safety standards, offering flexibility for installation and seamless integration into existing systems.

FAQs of Paddy Dryer Heat Exchangers:

Q: How does the paddy dryer heat exchanger improve drying efficiency?

A: Our heat exchanger maximizes thermal energy transfer through its high-grade copper tubes and stainless steel construction, resulting in enhanced paddy drying rates and more uniform moisture removal. Its 85% efficiency translates into faster processing times and reduced operating costs.Q: What are the key benefits of using high-grade copper tubes in this heat exchanger?

A: High-grade copper offers excellent thermal conductivity, improving heat exchange rates. It also resists scaling and corrosion, ensuring stable performance and a longer service life, making it ideal for demanding agricultural drying applications.Q: When should I consider maintaining or inspecting the heat exchanger?

A: Routine maintenance or inspection is recommended every 6 to 12 months, depending on usage levels. Checking for blockages, leaks, or performance drops ensures ongoing efficiency and helps maximize the products 10-year service life.Q: Where can the heat exchanger be installed within a drying system?

A: This heat exchanger is designed for horizontal installation, typically positioned between the heat source and the drying chamber. Its flexible, customizable design allows it to be fitted into new or existing paddy drying systems in a variety of facility layouts.Q: What processes does the heat exchanger support in paddy drying applications?

A: It transfers heat from steam or hot water to the air used in drying chambers, ensuring efficient thermal energy delivery to paddy batches. This process allows rapid moisture reduction while maintaining the integrity of the grains.Q: How do I benefit from the products corrosion-resistant materials and epoxy coating?

A: The stainless steel and epoxy-coated surface protect against rust and chemical attack, even in humid environments, reducing maintenance needs. This delivers long-term reliability, minimizes downtime, and extends the overall service life of the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

Rice Mill Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Max Pressure : 1.6 MPa

Thickness : 8 mm

Condition : New

Temperature : Other, Up to 150C

Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Max Pressure : Up to 25 bar

Thickness : 3 mm to 10 mm (as per design)

Condition : New

Temperature : Other, 10C to 200C

Industrial Heat Exchanger

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Max Pressure : 12 bar

Thickness : 6 mm

Condition : New

Temperature : Other, up to 180C

Marine Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Max Pressure : 2.5 MPa

Thickness : 35 mm

Condition : New

Temperature : Other, 10C to 120C

|

BADRIN INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry