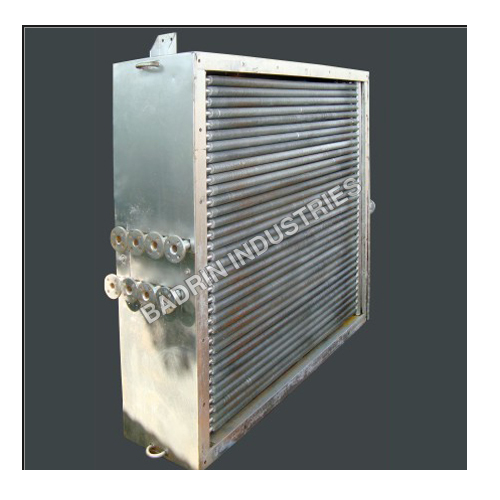

Heat Exchangers

Price 10000 INR/ Piece

Heat Exchangers Specification

- Thickness

- 3 mm to 10 mm (as per design)

- Air Volume

- Optional (for air-to-liquid types)

- Number of Pipe

- Varies (typically 16-100 tubes)

- Temperature

- -10C to 200C

- Diameter

- 100 mm 600 mm

- Max. Capacity

- Up to 50,000 kcal/hr

- Max Pressure

- Up to 25 bar

- Condition

- New

- Structure

- Shell & Tube / Plate Type

- Liquid Flow Rate

- Up to 7500 LPH

- Working Presssure

- Up to 25 bar

- Voltage

- 220-240 V / 380-415 V (as per requirement)

- Power

- Up to 250 kW (depending on design)

- Weight

- Varies as per model and capacity

- Dimensions

- Customized as per site requirement

- Connection Type

- Flanged / Threaded / Welded

- Application

- Chemical, Pharmaceutical, Food, Dairy, HVAC

- Mounting

- Horizontal / Vertical

- Testing

- Hydro/Pneumatic Test as per standards

- Tube Type

- Plain / Finned / Corrugated

- Surface Finish

- Epoxy/PU coated, Polished

- Material of Construction

- Mild Steel, Stainless Steel (304, 316)

- Heat Transfer Area

- 0.5 m² to 100 m²

Heat Exchangers Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 3-4 Days

- Main Domestic Market

- All India

About Heat Exchangers

We are engrossed in manufacturing, exporting and supplying a wide range of Industrial Heat Exchanger. This exchanger is perfect to transfer heat from one matter to another matter. Offered exchanger is widely used in air conditioning, industrial water heating, water cooling and condensing plants. For manufacturing this exchanger, our professionals use quality assured components and pioneering techniques. In addition, clients can avail this Industrial Heat Exchanger from us at pocket friendly prices.

Features of Industrial Heat Exchanger:

- High effectiveness

- Robust design

- Low maintenance

- Noise free operation

Applications of Industrial Heat Exchanger :-

- Sugar Mills

- Rice Mills

- Tea Industries

- Paper Industry

- Wood Drying

- Marine

- Pharmaceutical

- Oil Refineries

- Chemical Industry

- Food Industries

- Petroleum refining

Finned Tube Size : 300 mm to 3000 mm

Raw Fin Materials: Mild Steel, Carbon Steel, Stainless Steel, Copper, Brass, Aluminum

Raw Tubes Material: Mild Steel, Carbon Steel, Stainless Steel, Copper, Brass, Seamless Tubes, Hot Dip Galvanized & CDW Tubes

Advanced Construction and Versatility

Our heat exchangers are crafted from mild steel and premium stainless steel (304, 316), with surface finishing options like epoxy/PU coating and polished surfaces for enhanced protection and hygiene. Designed for long-lasting durability, they operate efficiently at pressures up to 25 bar and temperatures up to 200C. Available in both shell & tube and plate type structures, they can be tailored for horizontal or vertical installation as per your facilitys needs.

Precision Engineering for Varied Applications

Engineered to accommodate diverse industrial sectorsincluding chemical, pharmaceutical, food, dairy, and HVACthese exchangers range in heat transfer area from 0.5 m to 100 m and capacity up to 50,000 kcal/hr. We offer flexible flow rates, power, and voltage options, along with customized tube configurations, to optimize efficiency for every specific application.

Reliable Quality Testing and Customization

Every heat exchanger is rigorously tested with hydro and pneumatic methods in compliance with global standards, ensuring safe and reliable performance. Dimensions, tube numbers, and mounting styles are customized to site requirements, making our products an ideal solution for both standard and unique heat exchange demands.

FAQs of Heat Exchangers:

Q: How do I choose the right material of construction for my heat exchanger?

A: The choice between mild steel and stainless steel (304 or 316) depends on your applications corrosion risk, temperature range, and process fluid. Stainless steel is ideal for high-corrosion, food, or pharmaceutical applications, whereas mild steel suits less aggressive conditions.Q: What are the benefits of the available surface finishes like epoxy/PU coating or polished surfaces?

A: Epoxy/PU coatings provide robust corrosion resistance and are recommended for harsh chemical conditions. Polished surfaces are preferable for food and pharmaceutical processes, ensuring easy cleaning and maintaining product purity.Q: When is it better to use a shell & tube heat exchanger instead of a plate type?

A: Shell & tube exchangers are ideal for high-flow rates, larger heat transfer areas, and applications requiring high-pressure or temperature resilience. Plate-type exchangers are best for compact installations and when rapid heat transfer is needed with less fouling risk.Q: What testing is applied to your heat exchangers to ensure quality and safety?

A: Each unit undergoes hydro and pneumatic testing in accordance with industry standards to verify pressure resistance and structural integrity. This ensures reliable operation under working pressures up to 25 bar.Q: How are the heat exchangers customized for site and process requirements?

A: We offer customizable dimensions, tube numbers (typically 16100), tube types (plain, finned, or corrugated), mounting options, and connection types (flanged, threaded, welded) to suit your exact space, process, and installation needs.Q: Where can these heat exchangers be used effectively?

A: These units are highly adaptable for use in chemical, pharmaceutical, food, dairy, and HVAC sectors due to their range of construction materials, finishes, and compliance with industry standards.Q: What are the key advantages of your heat exchangers for exporters, manufacturers, and suppliers in India?

A: Our heat exchangers offer robust construction, customizable features, and adherence to international standards, making them suitable for a broad client base and export markets. Their efficiency, safety, and versatility provide significant value for manufacturers, suppliers, and end users across varied industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

Paddy Dryer Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Temperature : Other, Up to 150C

Weight : 1000 Kg

Liquid Flow Rate : 350 L/h

Dimensions : Customization Available

Industrial Heat Exchanger

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Temperature : Other, up to 180C

Weight : 250 kg

Liquid Flow Rate : 5 m/h

Dimensions : 1200 x 600 x 800 mm

Marine Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Temperature : Other, 10C to 120C

Weight : 3050 kg

Liquid Flow Rate : 1.25.8 m/h

Dimensions : 600 x 225 x 250 mm

Stainless Steel Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Temperature : Other, 20C to 150C

Weight : 250550 kg (customizable)

Liquid Flow Rate : 25006000 L/hr

Dimensions : 1200 mm x 400 mm x 900 mm (varies by model)

|

BADRIN INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry