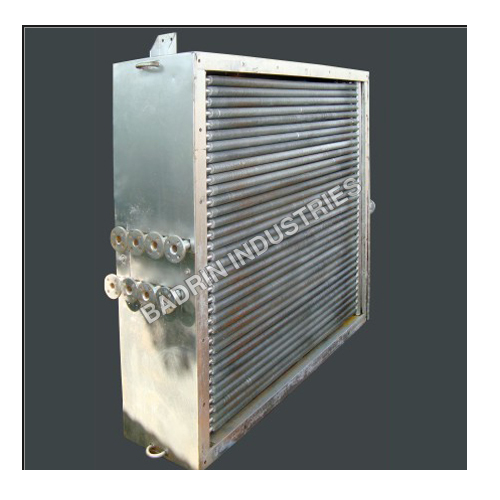

Stainless Steel Heat Exchangers

Price 10000 INR/ Piece

Stainless Steel Heat Exchangers Specification

- Thickness

- 2-5 mm

- Number of Pipe

- 12-60 tubes

- Temperature

- -20C to 150C

- Max Pressure

- 2.5 MPa

- Diameter

- 150-350 mm

- Max. Capacity

- up to 12000 L/hr

- Condition

- New

- Structure

- Shell and Tube

- Liquid Flow Rate

- 2500-6000 L/hr

- Working Presssure

- 1.0-2.5 MPa

- Voltage

- 220-415 V

- Power

- 5-20 kW (depending on application)

- Weight

- 250-550 kg (customizable)

- Dimensions

- 1200 mm x 400 mm x 900 mm (varies by model)

- Corrosion Resistance

- Excellent

- Usage/Application

- Industrial, Chemical, Food Processing, Pharmaceutical

- Leak Proof Design

- Yes

- End Connection

- Flanged/Threaded (customizable)

- Mounting Type

- Horizontal/Vertical

- Heat Transfer Area

- 2-8 m²

- Cleaning

- Easy Clean (Removable Tube Bundle)

- Material

- Stainless Steel 304/316L

Stainless Steel Heat Exchangers Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 3-4 Days

- Main Domestic Market

- All India

About Stainless Steel Heat Exchangers

With high dedication of our engineers, we are manufacturing, exporting and supplying a supreme quality range of Stainless Steel Heat Exchangers. Provided exchangers are widely appreciated for exchanging heat in food packaging, refinery and other allied industries. These exchangers are manufactured using optimum quality stainless steel and sophisticated techniques. In addition to this, clients can purchase these Stainless Steel Heat Exchangers from us in different specification at competitive prices.

Features of Stainless Steel Heat Exchangers:

- Corrosion resistance

- Smooth finishing

- Power efficient

- Easy maintenance

Engineered Versatility for Demanding Applications

These shell and tube heat exchangers are tailored for industrial, chemical, food processing, and pharmaceutical applications. With flexible end connections, mounting options, and a choice between stainless steel 304 or 316L, they easily adapt to specific process needs and installation requirements, providing assurance of longevity and compatibility.

Superior Safety and Reliability

Exceptionally resistant to corrosion and leaks, these exchangers ensure premium product purity and safe operation. Their robust design supports working pressures up to 2.5 MPa and temperatures from -20C to 150C, making them a dependable solution for even the harshest operating environments.

FAQs of Stainless Steel Heat Exchangers:

Q: How do I clean the stainless steel heat exchanger, and how often should it be maintained?

A: These heat exchangers are equipped with a removable tube bundle, making cleaning and maintenance straightforward. The frequency of cleaning depends on your application and the type of process fluids, but typically, inspecting and cleaning every 612 months ensures optimal performance and longevity.Q: What benefits does stainless steel 304/316L construction provide in heat exchangers?

A: Stainless steel 304 and 316L offer excellent corrosion resistance, ensuring durability in aggressive environments found in chemical, food, and pharmaceutical industries. 316Ls lower carbon content enhances resistance to pitting and chemical attack, making these exchangers a robust choice for demanding applications.Q: Where can these heat exchangers be installed, and what are the mounting options?

A: These units are suitable for use in industrial plants, chemical facilities, food processing units, and pharmaceutical operations. They can be mounted either horizontally or vertically, allowing installation flexibility to suit space and process flow requirements.Q: What is the process for customizing end connections or weight specifications?

A: End connections (flanged or threaded) and the units weight can be customized to meet specific installation demands. Simply specify your requirements during ordering, and our team will ensure the unit is tailored accordingly for seamless integration into your system.Q: When is it recommended to choose the higher power or larger heat transfer area models?

A: If your application demands higher heat loads, greater throughput, or rapid temperature changes, selecting models with larger heat transfer areas (up to 8 m) and higher power ratings (up to 20 kW) is advantageous. This ensures efficiency and stable performance for heavier-duty operations.Q: What is the maximum flow rate and pressure that these heat exchangers can handle?

A: Our models accommodate liquid flow rates up to 12,000 L/hr and operate safely up to 2.5 MPa, making them suitable for high-capacity and high-pressure processes across a variety of industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchangers Category

Rice Mill Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Working Presssure : 1.0 MPa

Weight : 1200 kg

Structure : tube Heat Exchanger

Max. Capacity : 7 Tons/hr

Industrial Heat Exchanger

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Working Presssure : 10 bar

Weight : 250 kg

Structure : Other, Shell and Tube

Max. Capacity : 50000 kcal/hr

Oil Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Working Presssure : 1.01.6 MPa

Weight : 120 kg

Structure : Other, Tubular/ Shell & Tube

Max. Capacity : 1000 L/H

Paddy Dryer Heat Exchangers

Price 10000 INR / Piece

Minimum Order Quantity : 5 Pieces

Working Presssure : 8 Bar

Weight : 1000 Kg

Structure : tube Heat Exchanger

Max. Capacity : 1500 Kg/h

|

BADRIN INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry